3D printing and design offer elementary, primary and middle school educators countless learning opportunities for enhanced student performance, engagement and learning. Check out our case studies for dozens of inspiring examples of real-life classroom learning.

As with all new technologies used in a school environment, educators need to understand the technology from a health and safety point of view.

All 3D printers produce VOP or Volatile Organic Particles during the printing process. VOPS are air-borne.

Four common filaments: acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polyethylene terephthalate (PET), and nylon emit VOCs or Volatile Organic Compounds even at temperatures below the printing temperature.

It is too early to tell the possible effects of short or long-term exposure to 3D printer emissions — think mobile phone usage back in 1999 — and there is no current research linking 3D printing to potential health issues. However, at Makers Empire, we believe that it’s better to be safe than sorry.

With this in mind, we are clear about the types of 3D filament and air filters we recommend to schools. But before we reveal our recommendations, let’s just go through a few basics for people new to 3D printing and design.

There are two main types of filters used in 3D printers:

HEPA is a standard for removing particles of .3um or greater. It does not remove gases. HEPA filters are ideal for vacuum cleaners, for example, as they remove smoke, soot and pollen, but they don’t actually prevent the major concern emissions of 3D printing. Thus, a HEPA filter will remove small particles but not VOC fumes.

Activated carbon charcoal filters remove VOCs emitted by 3D printing. Carbon filters are designed to trap much finer molecules, which are just a few hundred picometers in size through adsorption (not absorption). The gases that a carbon filer can trap would pass right through a HEPA filter without any effect.

In terms of 3D printing, it is unclear if a HEPA or carbon filter is more appropriate as both have their uses. What is clear, however, is that either type of air filter is a lot better than no filter and that a combination HEPA/carbon filter is the best.

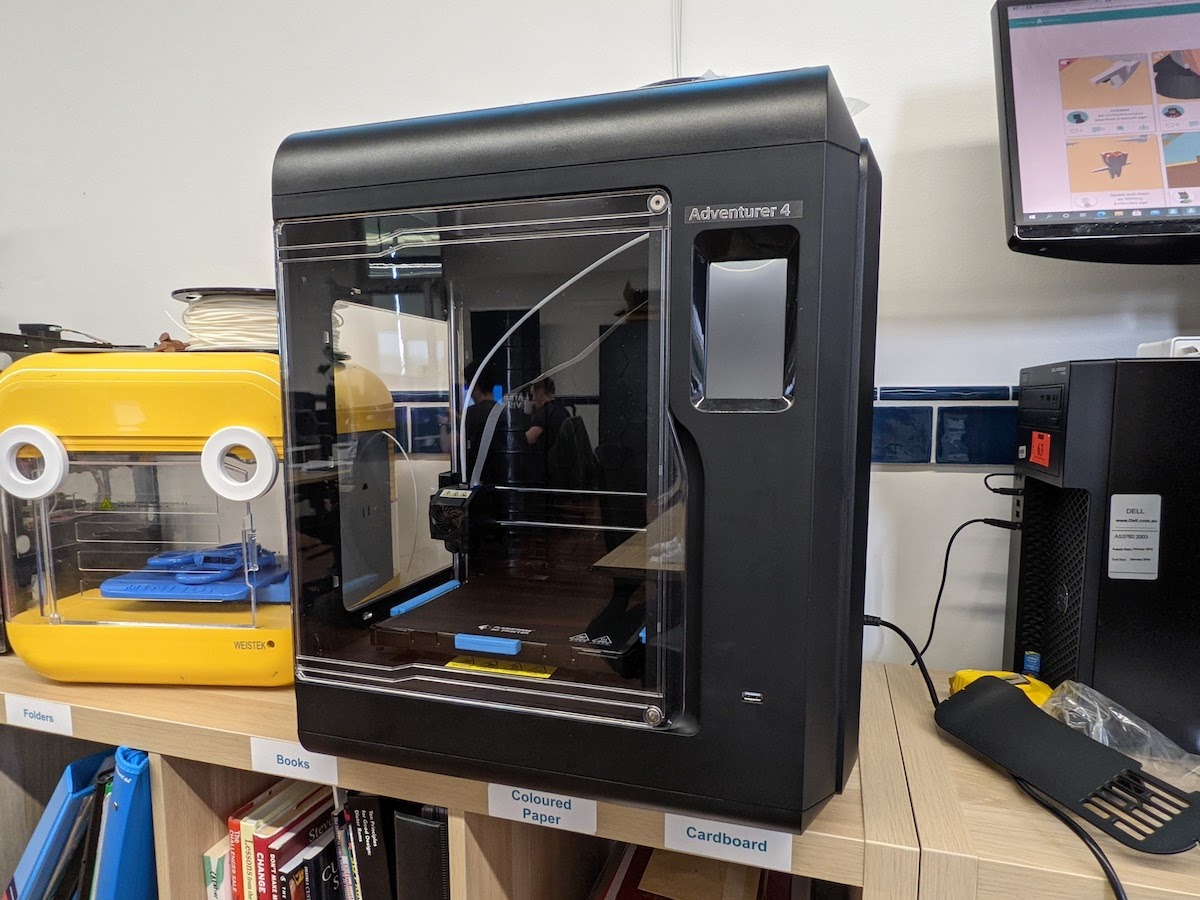

In terms of enclosed vs ‘open’ printers, many schools or school districts require 3D printers to be fully enclosed (i.e. no exposed moving parts). From an air filtration point of view, enclosed printers are probably better as open printers would require impractically large air filters to be effective.

In all cases, we recommend using 3D printers in a room with great ventilation (e.g. open doors and windows, put air conditioning/ air filter on etc).

More Reading

Makers Empire Recommendation: printers in a school, business or home environment should be enclosed and have a HEPA or carbon filter. Ideally, a printer should have both a HEPA filter and a carbon filter and be used in a well-ventilated area.

3D printers can use many different types of filament (consumable), including:

PLA plastic is shown to emit less (VOCs) than ABS plastic. There is some evidence that PLA-fed 3D printers may be less harmful than ABS-fed printers not only because of differences in emission rates, but also because PLA is actually biocompatible and used in a lot of medical procedures.

Makers Empire Recommendation: use only PLA plastic with 3D printers in a school environment.

HEPA filters can clog easily in a dusty environment, but you can easily tell it needs changing by its color. Each month, inspect the HEPA filter and replace it if it is no longer visibly clean as it will be only attracting dust, etc. You can run the printer without that filter, given that a HEPA filter alone has no effect on the gasses produced by printing filament.

With carbon filters, it depends on the filament you use. PLA filament produces very low amounts of VOCs so the carbon filter should easily last 500 hours or more or say a full year. With other filaments, like ABS, you’ll need to replace a carbon air filter more often, say every six months, as they produce higher quantities of VOCs.

Makers Empire Recommendation: change HEPA filters when the filter is visibly dirty and change carbon filters every six months (if using ABS filament) or every 12 months (if using PLA filament).

In response to customer demand, Makers Empire has created an online shop for 3D printers and 3D printing filament.

Makers Empire only sells 3D printing hardware products that we use ourselves. Plus, all our 3D printing hardware packages come with online training and world-class ongoing support. We want to make sure your 3D printing experience is a successful one!

Check out our Makers Empire 3D Printer Bundles.

Please wait while you are redirected to the right page...